UV DTF printing is quickly becoming one of the most talked-about technologies in the print industry, and for good reason.

Since Mimaki launched the UJV300DTF-75, its first UV DTF printer, it has opened the door to a whole new world of creative and profitable applications.

But what exactly is UV DTF, and why is it such a game-changer?

If you’re familiar with direct-to-film (DTF), you’ll know it’s been around for a while, mainly for garment decoration. UV DTF (ultra-violet direct-to-film), however, is something relatively new to the industry, and it’s transforming how we think about product decoration.

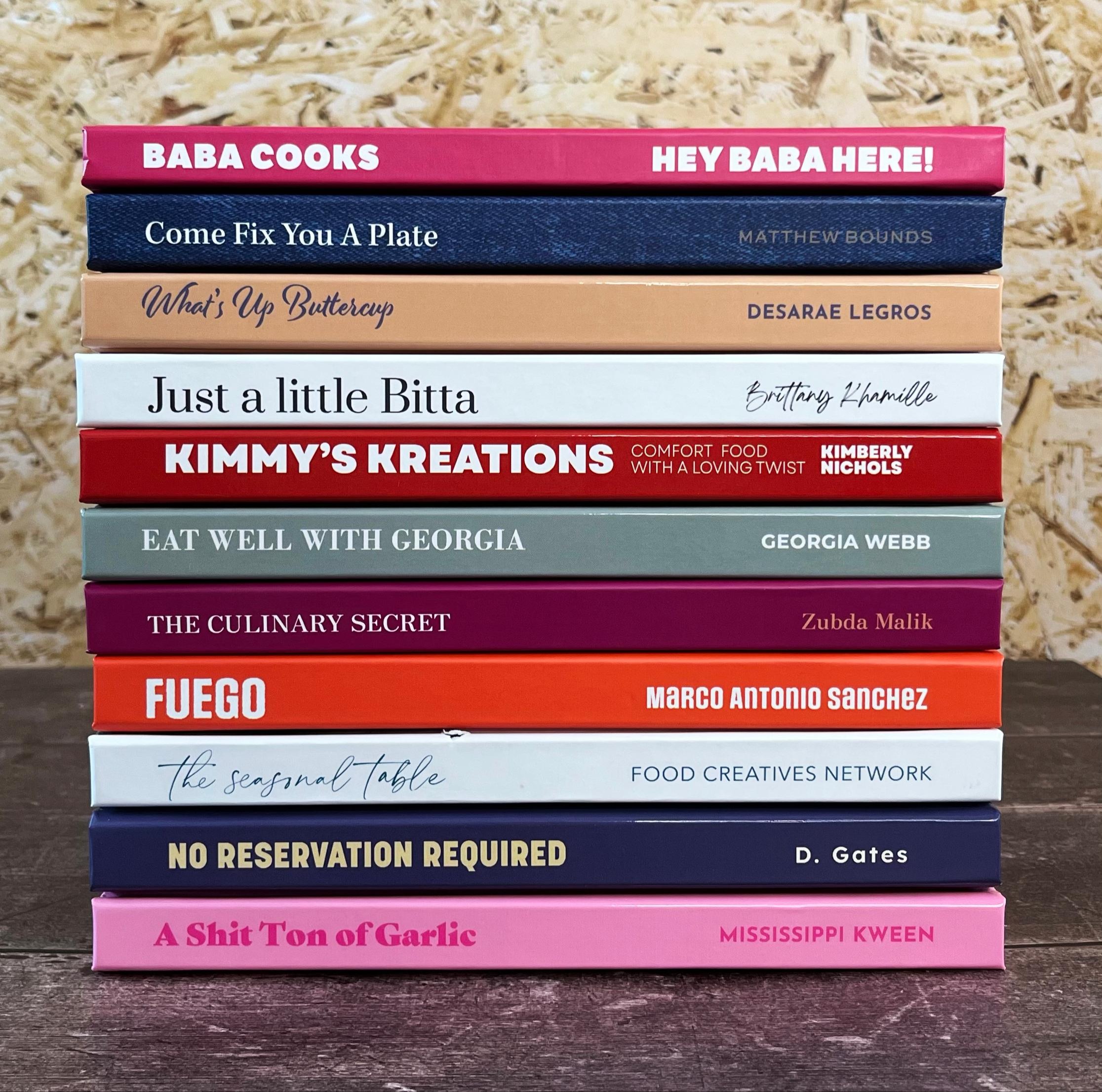

Put simply, UV DTF is a process that uses UV-curable inks printed directly onto a specialist film. These full-colour graphics can then be transferred onto surfaces that are usually considered “unprintable”, or at the very least, challenging due to shape, size or difficulty in putting in, or on a printer.

UV-DTF Printing Process

Watch the full insight video on the Mimaki UJV300DTF-75

https://www.youtube.com/watch?v=agWDJOjDbzA

Because the ink is instantly cured by UV light, the graphics are:

Durable – scratch and weather-resistant.

Flexible – able to adhere to uneven and awkward surfaces.

Fast – no need for drying time, cutting, or weeding.

This means print businesses can create high-impact graphics for a wide range of products in minutes, without the traditional pre or post-print work.

Why choose UV DTF for your business?

The real appeal of UV DTF lies in its versatility. Traditional printing methods often limit you to flat or coated substrates, but UV DTF makes it possible to decorate almost anything.

For print service providers, UV DTF opens the door to whole new revenue streams. It’s ideal for promotional products like bottles and phone cases, as well as short run packaging and mock-ups, but it also stretches into industrial uses such as car parts, appliance dials, and even tools; surfaces that are usually too awkward to print on with traditional methods.

Mimaki’s advantage goes further. Its UV inks are certified safe and non-toxic, earning a GreenGuard Gold certification. This makes printing with the Mimaki UJV300DTF-75 suitable for children’s products, from toys and puzzles to lunchboxes and stationery, opening up yet another market for personalised, durable graphics.

UV DTF isn’t just versatile, it’s a way to diversify with confidence and expand into sectors you may never have considered before.

With Mimaki’s UJV300DTF-75, you also benefit from:

With Mimaki’s UJV300DTF-75, you also benefit from:

No pre-treatment required – graphics stick to virtually any surface.

No heat presses or additional equipment – the process is all-in-one.

Energy efficiency – UV curing reduces power usage compared to alternative methods.

Time saved – less prep, less waste, more production.

In short, UV DTF is not just another print method; it’s a fast track to diversifying your offering, winning new customers, and boosting profitability.

How to Apply Mimaki’s UV DTF:

Once you’ve printed your design with the UJV300DTF-75, here’s how the transfer process works:

Trim your design – Cut close to the artwork for easier positioning.

Clean the surface – Use IPA (isopropyl alcohol) to remove dust or grease from hard surfaces.

Peel the film – Separate the clear film, leaving the print on the application layer.

Position the transfer -Take your time to line it up correctly.

Apply pressure – Use a squeegee or your fingers to press the design firmly.

Peel and reveal – Remove the application film to uncover your finished graphic.

That’s it! No weeding, no heating, no fuss. Just a clean, professional finish every time.

See Mimaki UV DTF for yourself…

Book a 1-to-1 demonstration with our team at the Hybrid showroom located in Crewe and discover how UV DTF can transform your business.

01270 501900

.jpg)

.jpg)