DTF Transfers Printers & Equipment

Direct to Film printing has revolutionised the world of garment decoration by offering an easy-to-use, versatile, and high-quality method for transferring designs onto a wide range of fabrics and surfaces. Whether for small home businesses or high-volume production environments, DTF is rapidly becoming a go-to solution primarily because of its flexibility, vibrancy, and efficiency.

In this guide, we’ll first explore how DTF transfers work, then highlight a selection of printer options—including the DTF Magic and Epson SC ranges—and finally explain the key consumables and equipment you’ll need to run a successful DTF setup.

What is DTF Transfer Printing?

DTF stands for Direct to Film. Essentially, this printing method involves printing a design directly onto a special film using DTF-specific inks, after which a powder adhesive is applied. Once cured, the transfer can be heat pressed onto a garment. Unlike traditional heat transfer vinyl or screen printing, DTF offers a soft feel, excellent durability, and full-colour printing with intricate detail—including gradients and photographic images.

Moreover, DTF is suitable for cotton, polyester, blends, nylon, and more, making it a brilliant all-rounder for apparel, bags, and promotional items.

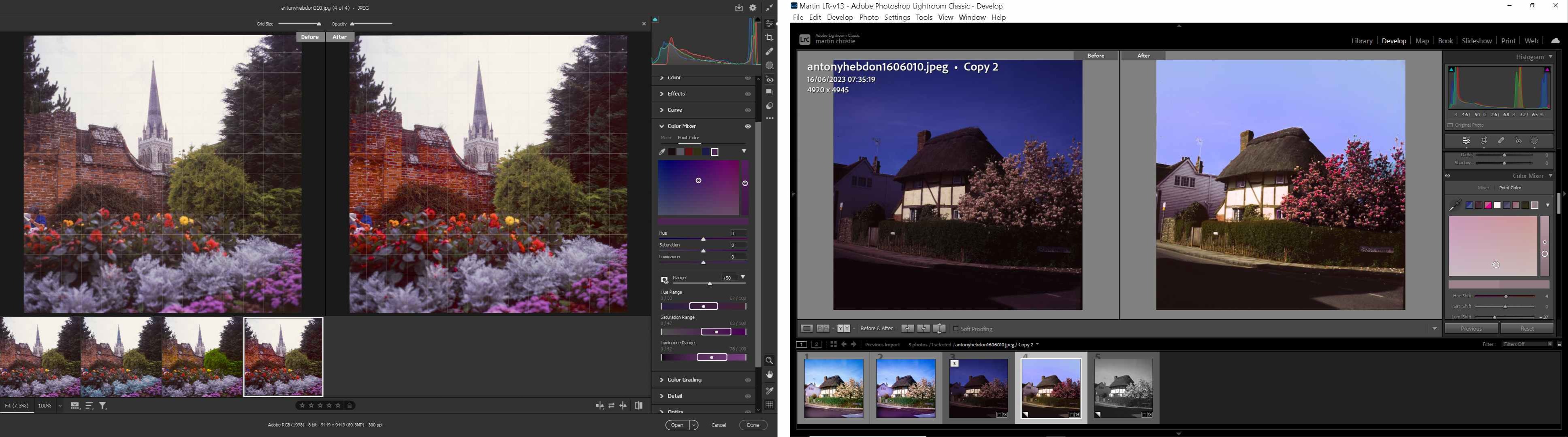

DTF Printer Options: From Entry-Level to High-Volume Production

Whether you’re just getting started or looking to scale your garment printing operation, there’s a DTF printer suited to your needs.

Below, here’s a breakdown of four leading models available today:

1.DTF Magic 30PRO Single Head DTF Printer (30cm Wide)

The DTF Magic 30PRO is an ideal entry point for those new to DTF or looking for a compact solution. With a 30cm print width, it’s perfectly suited to small-to-medium scale operations and offers professional print quality in a smaller footprint.

Print width: 30cm (A3+)

Print head: Original Epson DX11-F1080-A1

Ideal for: Start-ups, small print shops, and businesses adding DTF as an additional service

Key features:

Excellent colour accuracy

Stable print performance

Compact and space-saving

Paired with: DTF curing oven and heat press for a complete setup

This printer is a great way to explore the benefits of DTF without a large upfront investment, while still producing stunning results.

2. DTF Magic 60PRO 2-Head DTF Printer (60cm Wide)

As your production needs increase, the DTF Magic 60PRO 2-Head printer offers a significant step up in speed and output capacity. Its dual-head setup increases efficiency while maintaining crisp detail and vibrant colour.

Print width: 60cm

Print heads: 2 Epson Precision Core i3200

Ideal for: Medium-volume production environments

Key features:

Higher throughput with dual-head printing

Smooth and continuous workflow

Greater media handling flexibility

Paired with: DTF curing oven for manual production or Inline powder shaker system for automated production

This printer offers a fantastic balance between cost and performance, making it a solid choice for businesses ready to grow.

3. DTF Magic 60PRO 4-Head DTF Printer (60cm Wide)

For high-demand businesses, the DTF Magic 60PRO 4-Head printer offers unmatched productivity. With four Epson heads, it dramatically increases printing speed and is built to handle large volumes efficiently.

Print width: 60cm

Print heads: 4 Epson Precision Core i3200

Ideal for: High-volume production environments

Key features:

Fast production speeds

Reduced lead times

Precision engineering for long production runs

Paired with: Full auto powder shaker/dryer and industrial heat press

Perfect for garment decorators who need consistent, rapid output without compromising on quality.

4. Epson SC-G6000 DTF Printer (90cm Wide)

The Epson SureColor SC-G6000 is a robust 90cm-wide DTF printer, engineered with Epson’s legendary print technology. Perfect for DTF workflows due to its precision, reliability, and wide format capability.

Print width: 90cm

Print head: PrecisionCore MicroTFP. Unique to EPSON printers

Ideal for: Businesses needing larger designs or wide-format print rolls

Key features:

Trusted Epson quality and build

High resolution and smooth gradients

Built-in reliability features to reduce downtime

Paired with: Suitable powder adhesive system and heat press for wide-format transfers

While this requires a more specialised setup, it’s an ideal choice for companies already invested in Epson systems or looking to add wide format DTF to their services.

DTF Consumables: Ink, Film & Powder

To achieve top-tier results, you’ll need to pair your printer with high-quality consumables:

DTF Ink: Specially formulated CMYK and white inks that work with the print heads. The white ink lays a base layer, allowing colours to pop on any fabric colour.

PET Film: Heat-stable sheets with a matte or glossy finish, available in sheets or rolls depending on your printer type.

Hot-Melt Powder: Acts as an adhesive when heat cured.

Cleaning Solution: Essential for flushing the print heads and maintaining print quality.

All DTF Magic consumables are specially formulated to work perfectly with all DTF printers, ensuring consistently vibrant colours, strong adhesion, and professional-quality results.

Maintenance: Keeping Your DTF System in Top Condition

DTF printers, like any digital printer, require regular maintenance to keep them running smoothly:

Daily head cleaning: Prevents ink clogs, especially with white ink.

Nozzle checks: Done before each print job to ensure all channels are firing correctly.

Humidity control: White ink is prone to settling, so temperature and humidity in your workspace should be stable.

Waste tank management: Empty and clean regularly to prevent overflow.

Ink agitation: Some systems include automatic white ink stirring; otherwise, manual shaking is required to prevent separation.

By sticking to a simple maintenance schedule, you’ll dramatically extend the life of your print heads and avoid downtime.

Heat Presses for DTF Transfers

Once your design is printed and cured, you’ll need a heat press to complete the transfer to the garment. The choice of heat press depends on your production volume:

Swing-away or clam-shell presses: Great for low-volume setups or on-demand transfers.

Auto-open heat presses: Ideal for increasing efficiency and preventing scorching.

Pneumatic or dual-station heat presses: Perfect for high-volume workflows, especially in combination with 60cm or 90cm printers.

Key settings typically used for DTF pressing:

Temperature: 150–160°C

Time: 10–15 seconds

Pressure: Medium to firm

Peel: Cold peel or hot peel, depending on the film type

A quality heat press ensures good adhesion, colour vibrancy, and durability on the final garment.

DTF Transfers Printers & Equipment Conclusion:

Why DTF is the Future of Garment Decoration

DTF Transfers Printers & Equipment offer unmatched versatility, vibrant full-colour prints, and an efficient workflow that suits businesses of all sizes. Whether you’re just starting out with the compact DTF Magic 30PRO or operating a high-volume shop with the 4-head 60PRO, there’s a system to match your needs.

DTF Transfers Printers & Equipment combined with the right consumables, consistent maintenance, and a reliable heat press, DTF gives you the tools to print onto almost any fabric—quickly, colourfully, and cost-effectively.

+44 (0)1582 671444

.jpg)