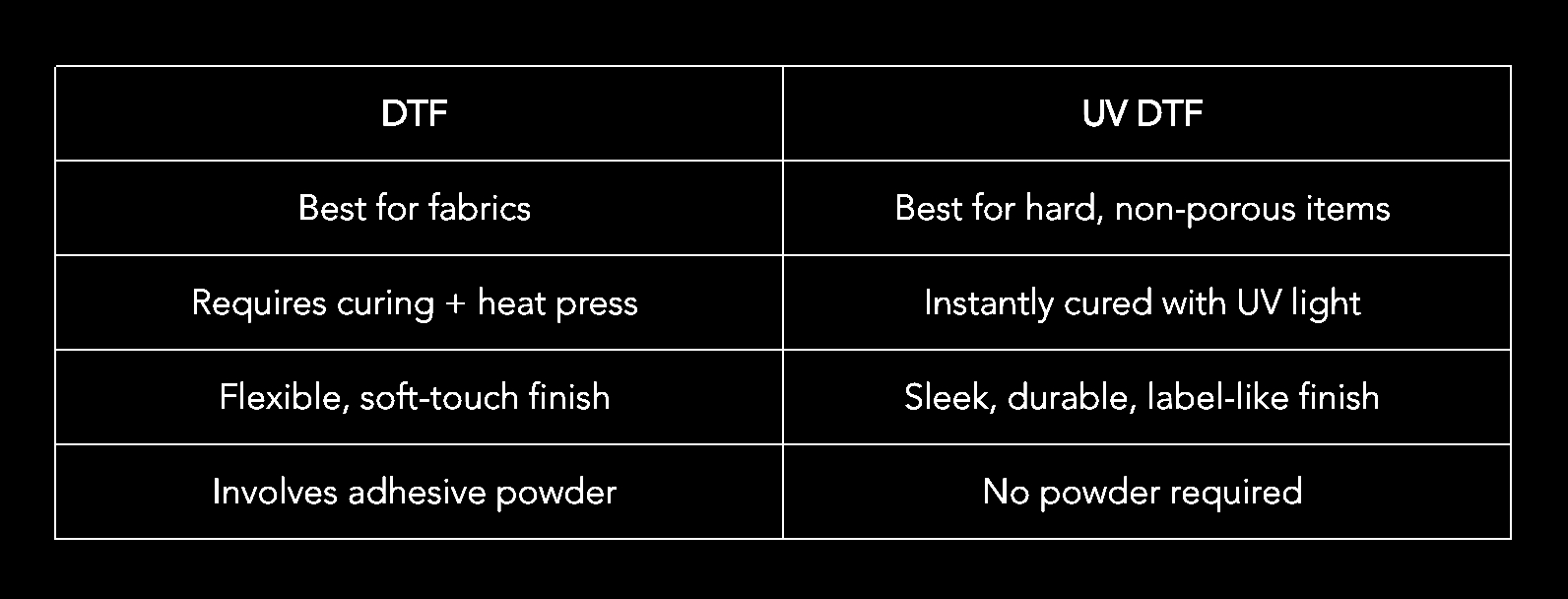

Printing technology moves fast, and one of the most common questions we hear is: what’s the difference between DTF and UV DTF?

The short answer: it’s all about the substrates you can print on, the workflow you follow, and the finish you get. Let’s dive in.

DTF vs UV DTF

DTF (Direct-to-Film) Printing

DTF is designed for textiles. Your design is printed onto PET film using CMYK and white inks, coated with adhesive powder, cured, and then heat-pressed onto garments.

✅ Perfect for: cotton, polyester, blends, and other fabrics

✅ Flexible, durable prints with strong wash resistance

✅ Requires oven curing and a heat press

UV DTF Printing

UV DTF is engineered for harder substrates. The design is printed directly to an A/B film with UV-curable inks, cured instantly with UV light, and transferred straight onto the product.

✅ Perfect for: mugs, bottles, phone cases, tiles, glass, and rigid substrates

✅ No oven or heat press required

✅ Fast workflow with sharp, vibrant finishes

Key Differences At A Glance

Which Technology Should You Choose?

Choose DTF if your focus is apparel and textile products.

Choose UV DTF if you want to customise hard goods with fast turnaround and durable results.

Many businesses run both side by side to offer a complete product range.

Featured Resolute Printers

At Resolute, we provide both DTF and UV DTF solutions. Here are our leading systems:

DTF Printers

R-Jet PRO DTF V8i – High-volume powerhouse for production environments.

R-Jet PRO DTF V4i – Mid-range workhorse combining speed and value.

R-Jet PRO DTF mini – Compact desktop printer, perfect for startups and small spaces.

UV DTF Printers

R-Jet PRO DTF UVi – Space-saving UV system for hard substrates.

R-Jet PRO DTF UV61 – Larger format UV DTF printer for speed and versatility.

The Bottom Line

DTF: For garments and fabrics.

UV DTF: For hard goods and rigid surfaces.

Resolute: The UK’s trusted source for both technologies.

Explore the full range of Resolute DTF and UV DTF printers and check out the DTF Hints & Tips.

01246 202686

.jpg)